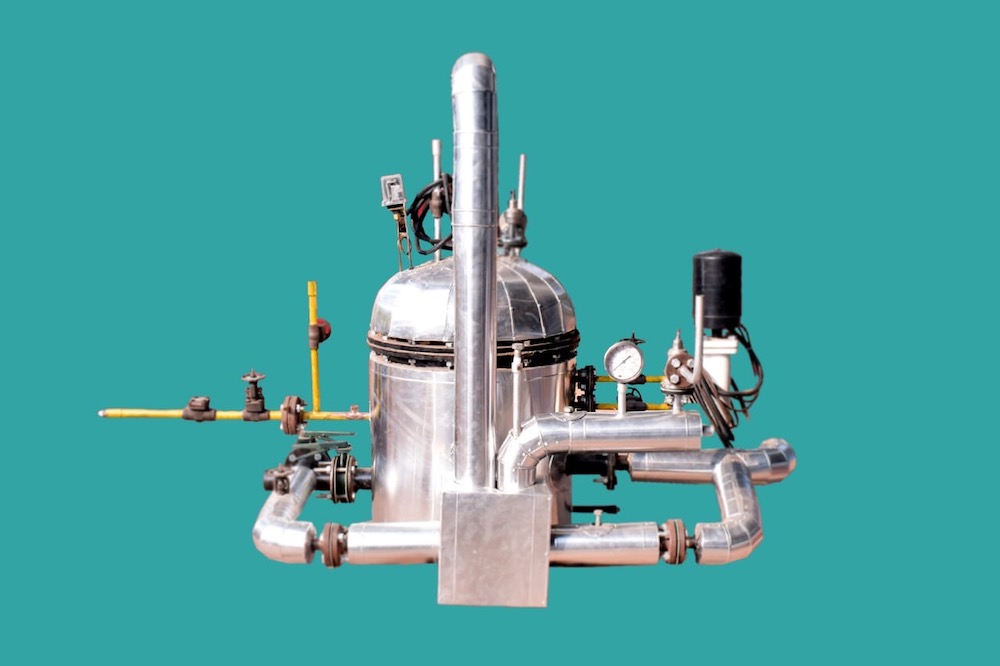

Heat Pipe Heat Recovery System

Heat Pipe Heat Recovery System

Trust Well Engineers is in waste heat recovery solutions company since 2016. Over the period of time our market survey shows that there is huge demand for low temperature waste heat recovery over all in industry verticals such as food and pharm, chemical industries, automobile and many more.

Being waste heat recovery system designer Trust Well Engineers developed innovative waste heat recovery system called Heat Pipe Technology Waste Heat Recovery System, to recover max waste heat in flue gas of DG sets .Incinerator, Waste process gases. Waste heat further can be used to generate steam, hot water or hot air from DG exhaust / Incinerator exhaust, process gas exhaust to cater the industry requirement and save on fuel running costs.

Trust Well Engineers Technologies innovative design offers very less time for warm-up load and also 1/3 rd. compact design. Trust Well Engineers provide this waste heat recovery system with variety of capacities, sizes etc. as per customer requirements and input specs.

Waste Heat Recovery system can be used to recover waste heat from flue gas generated in oil / gas fired DG, Oil/Gas / Coal fired boilers / Hot air generators, Thermal oil heaters, Hot Water generators, Steam boilers etc.

Trust Well Engineers system can recover waste heat from flue gas having temp range up to 450 degree C and below up to 180 deg C for special gas fired application.

Trust Well Engineers developed innovative HEAT PIPE technology & successfully designed 1/3 rd compact, technically most suitable application for the same output in comparison with conventional WHRS available in the market.

Heat pipe consist of suitable MOC tube encased with highly stable organic compound formulation under vacuum. Trust Well Engineers group company M/s Bleachchem has a special Organic compound manufacturing facility along with extensive R and D facility to produce appropriate organic solution for various waste heat application. Heat pipe System literally works as rapid heat transfer technology with sonic super speed.

Heat Pipe Tube is divided into evaporator section at the bottom and condenser section at top. When bottom portion comes in contact with hot flue gas pass, internal organic compound rapidly evaporates, vapors & associated heat of vaporization is transferred to top portion at sonic speed. Top portion is kept surrounded by heat absorbing media such as air /steam / hot oil. After exchange of rapid heat to surrounding, organic compound vapor gets condensed and flows back to evaporator due to wick and capillary action

This evaporation and condensation cycle continues as long as flue gas is available and heat absorption take place on the other side.

Due to inherent reliability, Heat Pipe technology first used by NASA for shuttle frictional heat dissipation.

Trust Well Engineers Technology developed state of art Heat Pipe manufacturing facility as per waste heat input properties and output specification to be met. Special Organic compound specs are decided as per the flue gas properties and end application.

Trust Well Engineers has its group company Bleach Chem as special organic compound manufacturing facility in house along with R & D facility.

We welcome your valued enquiry to explore this technology which saves foot print area, structure support cost suitable to handle corrosive waste gases

Heat pipe developed by Trust Well Engineers can be used for very high temp 2000 deg.C to 2500 deg. C on request.

IIT Pawai is exploring this technology for their pilot project of DG set based Waste Heat Recovery .

Feel free to contact us for more details.