Soot Blowers

We have been Certified by Engineers India Limited (EIL) Six years back,

In an Industrial Boiler to clean, soot/ ash/ slag accumulation on the surface of coils/ tubes results in the reduction of heat transfer. Soot deposition can also erode and corrode metal surfaces. It is necessary to remove this accumulation daily in order to increase efficiency of Boiler and life of the tubes/ coils.

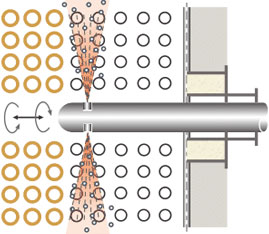

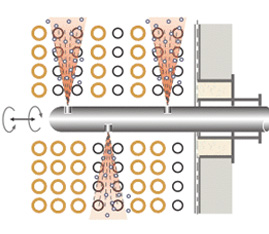

Effective cleaning of soot is the most important aspect of any boiler performance. TRUST WELL SOOT BLOWERS uses Advance Design Spray Nozzles for effective cleaning using Steam jet energy.

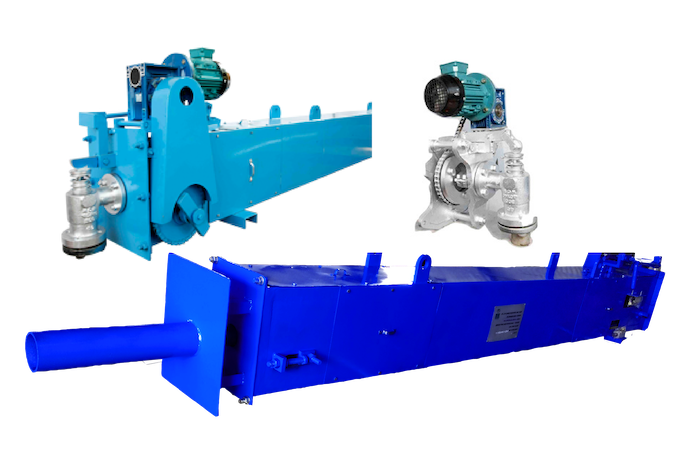

Trust Well offers a complete range of Soot Blowers to suit various requirements of the Boiler for different temperature Zones.

Trust Well has tailor-made solutions for cleaning Boiler Tubes/ Coils, which improves Boiler efficiency.

With years of expertise as a Soot Blower manufacturer, Trust Well focuses not only on cleaning but on improving overall boiler efficiency and performance. Clean heating surfaces significantly reduce fuel consumption and emissions, making our Soot Blowers a valuable investment for both economic and environmental benefits.

All Soot Blowers can be connected to PLC based Sequential Control Panel as per requirement of indoor/ outdoor conditions.